3-Phase Induction Circuits:

Quantities Used in 3-Phase Induction Circuits:

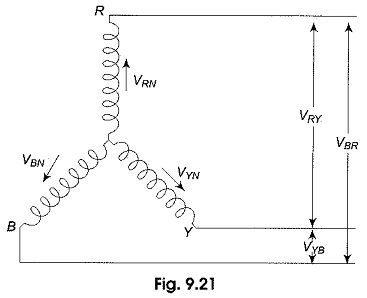

Phase Voltage (V_ph):

Phase voltage is the voltage across a single phase of a 3-phase system. In a balanced system, the phase voltage is equal to the line voltage divided by the square root of 3 (V_ph = V_line / √3).

Line Voltage (V_line):

Line voltage is the voltage between any two phases in a 3-phase system. It is higher than the phase voltage in a balanced system by the square root of 3 (V_line = √3 * V_ph).

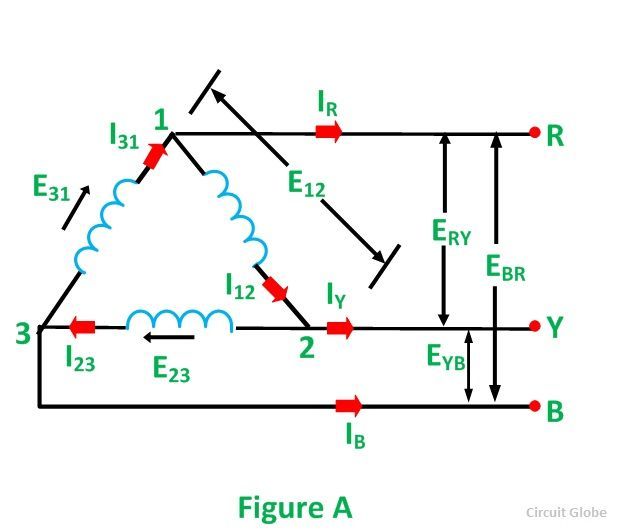

Line Current (I_line):

Line current is the current flowing through one of the lines connecting the source to the load in a 3-phase system. It is higher than the phase current in a balanced system by the square root of 3 (I_line = √3 * I_ph).

Phase Current (I_ph):

Phase current is the current flowing through one phase of a 3-phase system. In a balanced system, it is equal to the line current divided by the square root of 3 (I_ph = I_line / √3).

Power Factor (PF):

Power factor is the cosine of the angle between the voltage and current waveforms in a 3-phase circuit. It indicates how effectively electrical power is being converted into useful work. Power factor values range from 0 to 1.

Frequency (f):

Frequency is the number of cycles per second of the alternating current in a 3-phase system. In many regions, including India, the standard frequency is 50 Hz.

Innovative Practical Applications of 3-Phase Induction Circuits:

Industrial Motors:

3-phase induction motors are widely used in industrial applications due to their reliability and efficiency. They power various machinery and equipment in manufacturing plants, conveyor systems, and pumps.

HVAC Systems:

Heating, Ventilation, and Air Conditioning (HVAC) systems often employ 3-phase induction motors for air handling units, chillers, and pumps. These motors provide consistent and controlled airflow.

Electric Vehicles:

The traction motors in electric vehicles often use 3-phase induction motor technology. These motors provide efficient and reliable propulsion, contributing to the electrification of transportation.

Renewable Energy:

3-phase induction generators are used in some wind turbine systems. They convert mechanical energy from the rotating blades into electrical power, contributing to renewable energy generation.

Compressors and Fans:

3-phase induction motors are utilized in compressors and fans for applications such as refrigeration systems and ventilation. They offer variable speed control and high torque capabilities.

Water Pumping Stations:

Water pumping stations for irrigation, municipal water supply, and wastewater treatment often use 3-phase induction motors to drive pumps. These motors are capable of handling varying load conditions.

Mining Operations:

3-phase induction motors power various equipment in mining operations, including crushers, conveyors, and drilling machines. They are favored for their robustness and ability to operate in harsh environments.

Paper and Pulp Industry:

In the paper and pulp industry, 3-phase induction motors drive machines for cutting, printing, and processing. Their reliability and ability to handle heavy loads make them suitable for such applications.

Air Compressors:

Industrial air compressors, used in manufacturing and construction, often rely on 3-phase induction motors for efficient and continuous operation.

Oil and Gas Sector:

3-phase induction motors find applications in the oil and gas sector, powering pumps, compressors, and drilling equipment. They are chosen for their durability and ability to operate in challenging environments.

Automated Systems and Robotics:

3-phase induction motors play a role in automated systems and robotics, providing the necessary torque and speed control for precise and efficient movement in manufacturing and assembly processes.

High-Speed Rail Systems:

Some high-speed rail systems use 3-phase induction motors in their propulsion systems. These motors offer high power density and are well-suited for the demands of rapid acceleration and deceleration.

The versatility of 3-phase induction circuits makes them integral to a wide range of applications, contributing to the efficiency and automation of various industries. Ongoing research and development continue to enhance their performance and applicability in emerging technologies.

Understanding the Basics of Electrical Load Calculation

Understanding the Basics of Electrical Load Calculation

When it comes to managing your electrical systems, understanding how to calculate your electrical load is essential. By using an electrical load calculator, you can determine the electrical load requirements for various appliances, ensuring that your electrical system functions efficiently and safely. In this section, we will explore the importance of electrical load calculation and how using an electrical load calculator can benefit your business.

Efficiency is crucial in any electrical system, and proper load calculation plays a vital role in achieving this. By accurately determining the electrical load requirements, you can ensure that your electrical system is neither underutilized nor overloaded. Underutilized systems lead to wasted energy and increased costs, while overloaded systems can lead to overheating, equipment damage, and potential safety hazards. Therefore, understanding the basics of electrical load calculation is vital for maintaining an optimal and safe electrical setup.

Using an electrical load calculator eliminates the guesswork involved in determining the electrical load requirements for your appliances. These calculators allow you to input specific information about each appliance, such as its power rating, usage duration, and frequency of use. Based on this data, the calculator provides you with accurate calculations of the electrical load, allowing you to make informed decisions about your electrical system's capacity.

One advantage of using an electrical load calculator is that it helps you identify potential energy-saving opportunities. By analyzing the load requirements for each appliance, you can identify energy-efficient alternatives and make informed decisions about equipment upgrades or replacements. This not only helps reduce your energy consumption but also lowers your utility bills in the long run.

In addition to energy efficiency, safety is another critical aspect of electrical load calculation. By understanding the maximum load capacity of your electrical system, you can ensure that you don't exceed its limits and risk overloading the system. This minimizes the chances of electrical accidents, such as electrical fires or short circuits, which can have catastrophic consequences.

Moreover, using an electrical load calculator can help you plan for future electrical needs. If you are considering adding new appliances or expanding your business operations, understanding your current load capacity will enable you to assess whether your electrical system can accommodate these changes. It allows you to make informed decisions without compromising the safety and efficiency of your electrical setup.

In conclusion, understanding the basics of electrical load calculation is crucial for managing your electrical systems efficiently and safely. By utilizing an electrical load calculator, you can accurately determine your electrical load requirements, identify energy-saving opportunities, ensure electrical safety, and plan for future needs. Incorporating this knowledge into your business practices will not only optimize your electrical system's functionality but also reduce energy costs and enhance safety. Mastering your electrical load with the ultimate calculator guide will empower you to make informed decisions that benefit both your business and the environment